In the world of fencing options, one type has held its ground for decades thanks to its security, practicality, and affordability—the chain link fence. From residential properties to industrial facilities, parks to playgrounds, this versatile fencing solution has cemented its place as one of the most popular choices. While it may be one of the simplest kinds of fencing, how chain link fence is made is actually quite interesting.

A chain link fence, characterized by its strength and durability, is an integral part of numerous home and business security solutions. Made from galvanized steel or aluminum, chain-link fencing has been around for nearly 150 years–maybe that’s why it’s such a familiar sight.

It has stood the test of time because of its functionality and versatility. Beyond fencing, this chain link can be used for dog runs or kennels, support for climbing plants or hedges, erosion control, and much more. If the drab look of galvanized fencing leaves you cold, chain-link fencing can be covered in colored vinyl to spruce it up a bit.

For extra privacy, slats or netting can be added to obscure the view of look-loos and even an added measure of security. And with the right machinery, several hundred feet can be produced in a short amount of time. These advantages have made chain link fencing almost a three-billion-dollar industry.

How The Magic Happens

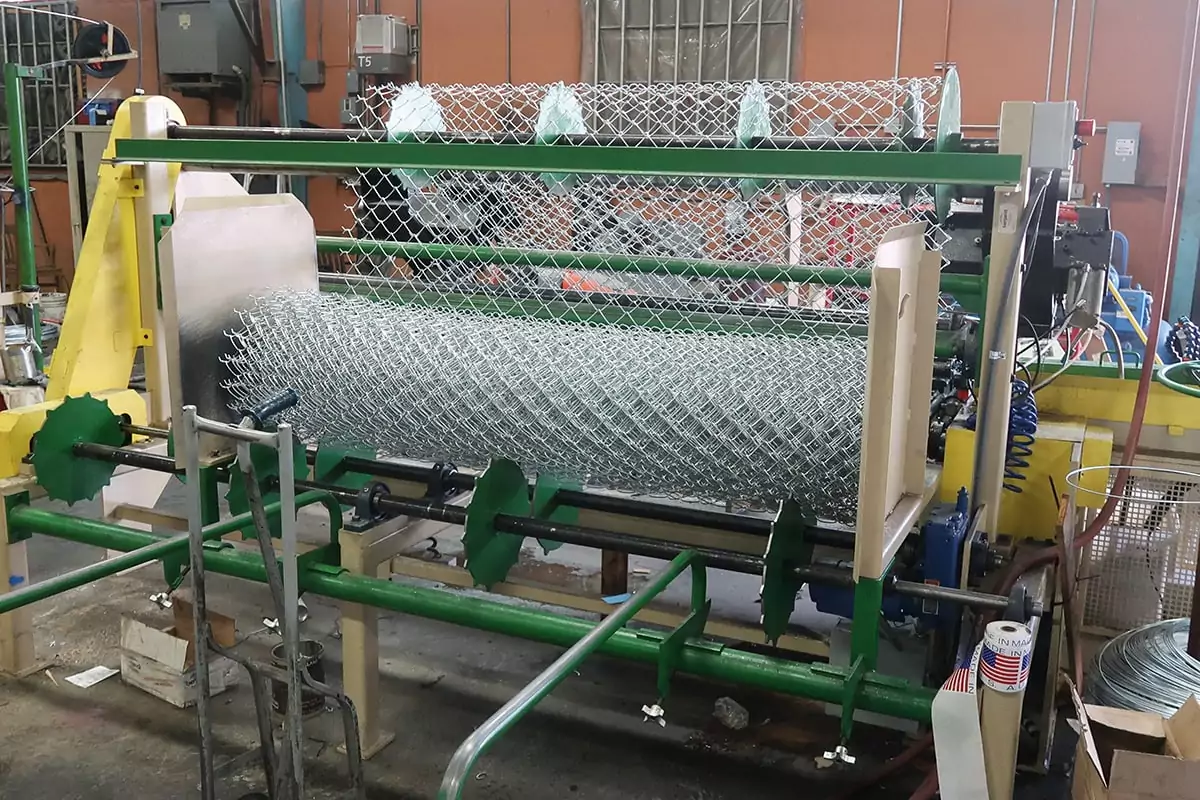

Let’s take a closer look at the machinery that makes this fencing–we think it’s a pretty cool piece of equipment. With the ability to bring two different spools of wire together to make the familiar diamond-shaped fencing, the chain-link weaving machine should be a staple in any fencing company’s arsenal.

First, two lines of wire are fed into the machine and pulled through a series of pulleys to straighten it out and create a little bit of tension. The machine can be programmed to handle different thicknesses in the line and how big to make the diamonds in the fencing.

Both wires are then bent in a zig-zag pattern so they can be intertwined with a spinning arm. That spinning continues as this new row of wire is linked to the row right above it. Once it reaches the right length, the wires are cut, the weave is shifted up, and the next row is created.

Before the fencing is shifted up, both ends of the row have two loose, pointy wires to deal with. There are two options at this point: either twist the two together or “knuckle” them together. This is the process of bending the ends over one another to keep them tied together. After all, if these ends aren’t secured, the fence would unravel pretty easily, right?

As the rows are brought together and shifted up, there is another arm that the weave must go over to keep the tension. The fencing is then rolled as it gets longer. Although there’s no limit to how long the fence can get, Pacific Wire Fencing only makes 50-foot rolls. Much more than that and the fencing gets a little difficult to deal with.

Once that length is reached, a wire is removed to disengage that length of fencing from the one behind it. Now you have an easy-to-manage roll of chain-link fencing, ready to be installed at your home, business, athletic field, or whatever else you need it for.

How Chain Link Fence is Made: Vinyl Coating

For chain link fences that are coated in vinyl, you may think it happens after the fence is made. Actually, the vinyl is added to the fencing wire before it’s fed into the machine. This process is almost as interesting as the fence weaving production!

You start with the same wire that is used in the fencing, and a series of pulleys that again are meant to keep the line straight and taught. The wire is run through a compartment where vinyl pellets are heated to 350 degrees to make it easier to apply to the wire.

Once it leaves that area, it is immediately run through a relatively long cold bath station where the vinyl becomes rigid almost immediately. That wire is then spooled up, cut, and delivered to the weaving machine where that process begins again.

Pacific Fence and Wire offers a variety of chain link fencing, posts, fittings, and accessories for your project. If you need help designing a fence, figuring out how much material you need, or just want us to take care of everything, don’t hesitate to reach out. We have more than 100 years of experience installing fences around the greater Portland Metro area.